Lena Maint Processes

Preventive maintenance is a system of periodic asset maintenance before a failure occurs. A preventative maintenance system supported by CMMS reduces the incapacity period by 65% and the overall costs by half. You can examine the differences created by CMMS in the example process

Planning

Periodic maintenance order is planned.

Easily access all information about the asset while planning, instant data you receive from the unit helps you decide when maintenance should be done.

Choose which technician is the fit for the work. Does the machine need oiling? Or is it optimizing the performance of a valuable and essential asset?

Entry of work to the System

Task is scheduled and prioritized.

Make sure work gets done by the right person at the right time by viewing the entire maintenance schedule.

Make the necessary adjustments quickly by grabbing and sliding tasks, don't waste time creating tasks repeatedly when you need to change.

Service Performing

The technician learns his future tasks by notification and carries them out.

Be on track of the technician's productivity with KPI measurements. How long does it take for the technician to work on the asset? What checks and interventions took place?

Track the completion percentage of the service in chronological order. Lena Maint will notify you of tasks that exceed the target time.

Closure

When the work is completed, it is reported and saved in both technician and equipment information.

View used spare parts and actions taken in the service report.

Avoid overlooked tasks with customized reports that automatically send you when the task is complete.

Analysis

Work order reports are analyzed and used in improvements.

Be informed about the recurrent failure.

Reduce your maintenance expenses by using reports and analysis to improve your preventive maintenance process.

DISCOVER LENA MAINT SOLUTIONS

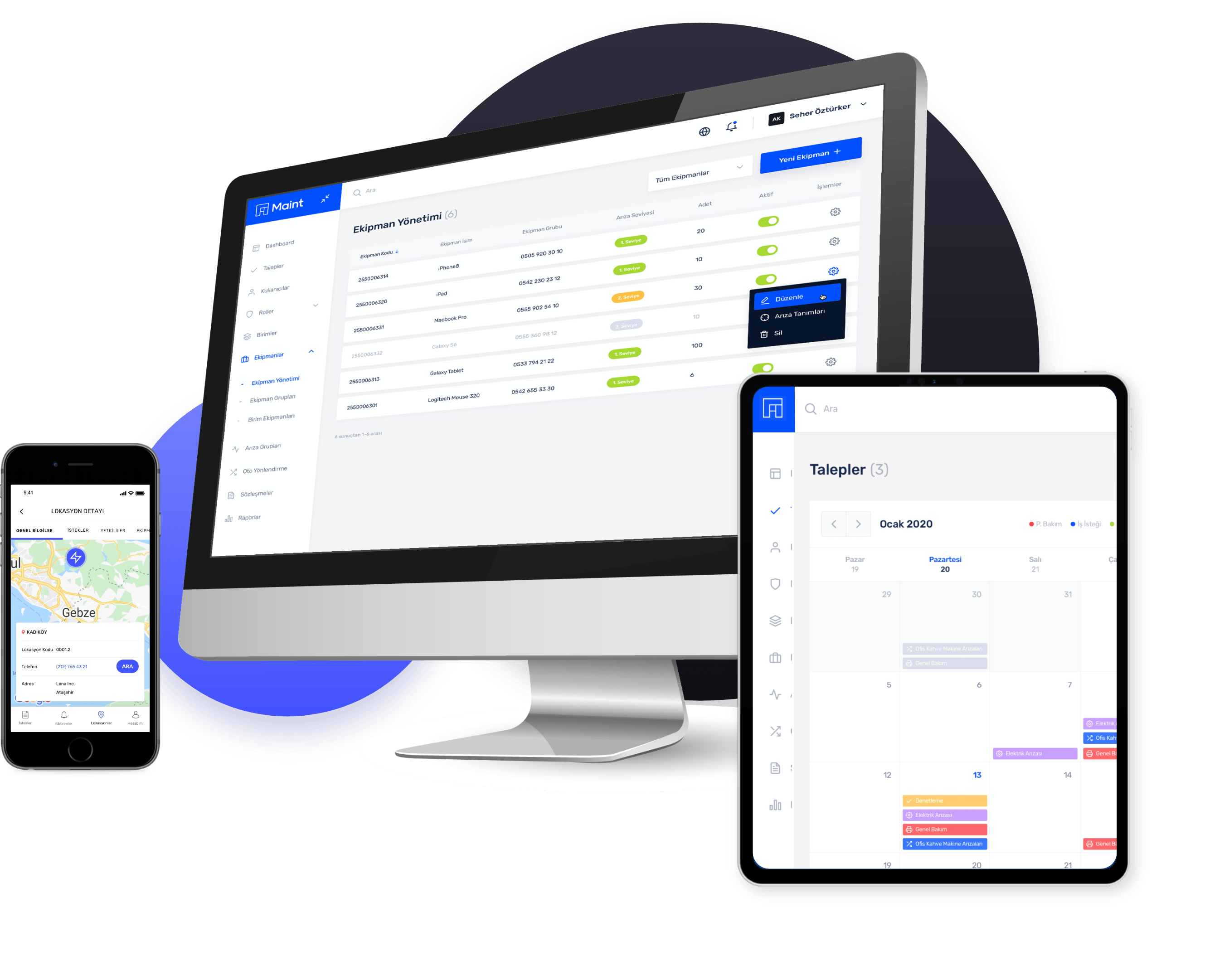

#1 platform to help you digitize, scale and manage maintanence processes

Work Order Management

Asset Management

Preventive Maintenance Management

Reporting and Analysis

Vendor & Contractor Management

Dynamic Scenario Planning

Operational Management

Rule Management

Manage Anytime, Anywhere

Easily manage your requests with Maint's mobile applications.